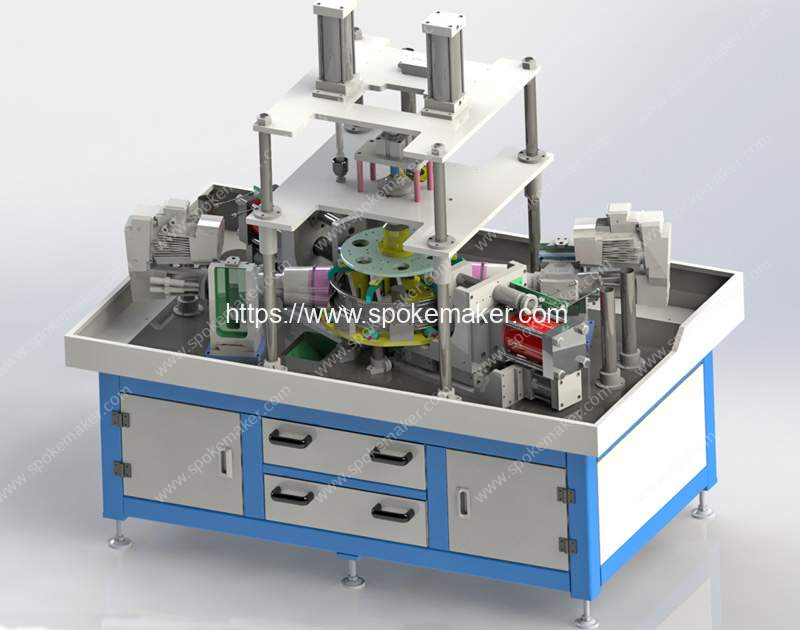

Hydraulic Type Motorcycle Rim Dimple Hole Punching Machine is used to make double lane dimple hole which at different direction and angle. It need compressed air for clamping and hydraulic power for drilling and dimple shape forming.

Hydraulic Type Motorcycle Rim Dimple Hole Punching Drilling MachineMachine have total 4 hydraulic dimple shape punching device and 4 pieces hole drilling device. When working, it first make the dimple shape, then rotary to the next position for the hole drilling. (for 36hole aluminum rim)

Specification of Hydraulic Type Motorcycle Rim Dimple Hole Punching Machine

- Main Machine: 1960*1160*1950mm

- Hydraulic Station Size: 630*465*800mm

- Control Cabinet: 1000*450*980mm

- Compressed Air: 0.2nm3/min

Working Video of Hydraulic Type Motorcycle Rim Dimple Hole Punching Machine

Company Profile

Romiter Group is a market-leading designer and a manufacturer of bicycle spokes and motorcycle spokes making machines, which wins a wide reputation for products with high efficiency, excellent reliability, easy maintenance and long lifespan.

We provide a complete bicycle and motorcycle spokes and nipple making solution, which includes Bicycle Spokes Making Machine, Bicycle Spokes Nipple Making Machine, High Speed Motorcycle Spokes Making Machine, Motorcycle Spokes Nipple Making Machine, Butted Spokes Making Machine, Bladed Spokes Making Machine, Wire Straightening Cutting Machine Machine, Wire Rivet Making Machine, Cycle Spoke Nipples Packing Machine, Ellipse-shaped Spoke Making Machine, Cycle Rim Making Machine, etc.